What is Total Light Intensity, also known as Cumulative UV Exposure?

(Also known as Total Illuminance, Integrated Light Intensity, or Cumulative Exposure)

Getting a high-quality UV cure is dependent on 2 things - light wavelength and total light intensity. Here, we’ll address the latter of the two. Total light intensity is also sometimes referred to as integrated light intensity, or total illuminance.

But what exactly is it? Simply put, total light intensity is a measure of illuminance over time and space. Its relationship to time, energy, and area can be expressed as illuminance x seconds = J (joule) / cm², with illuminance being the intensity of light.

UV curing has demands a lot of energy, so it is crucial to have a good idea of how many joules a specific application will need. So, let’s look at a few of calculations.

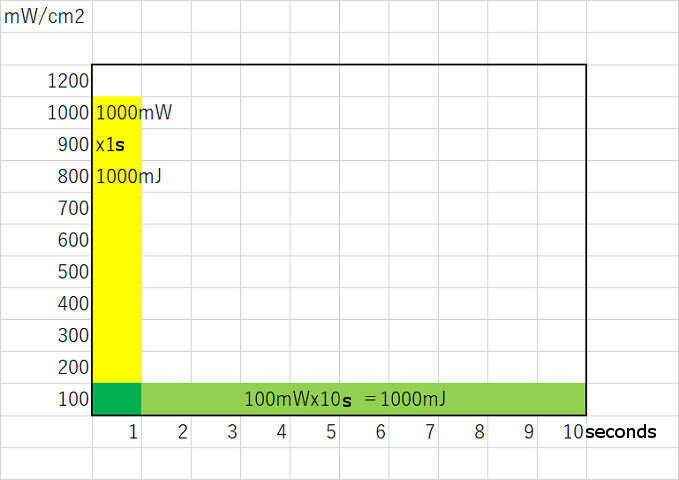

Below, we have a table showing 2 different levels of light intensity in relation to time. Pretend we’re comparing a powerful irradiator (yellow) against a weaker irradiator (green). Can we achieve the same total light intensity? And can we achieve the same quality of curing with each irradiator?

The yellow area of the table represents our “powerful” illuminator - it runs with an illuminance of 1000 mW/cm² for the span of 1 second. Using our trusty formula, we find that our total light intensity at the end of that 1 second willl be 1000 mJ / cm².

Micro Square demonstrating how to measure total illuminance. Use translated captioning if needed!

The green area in the table is our “weak” irradiator. It runs with an illuminance of 1000 mW/cm ². But, if we run it for 10 seconds, we can still get that total light intensity is 1000mJ / cm² .

In other words, a source of weak illuminance can generate the same amount of accumulated light as a powerful one if it’s given more time.

But on to our second question - will it cure as well? Well, the answer is maybe. UV curing materials tend to have a required minimum illuminance.

If we extrapolated our table and example from above, we should be able to run a 1 mW/cm² irradiator for 1000 seconds and get the same 1000 MJ/cm² integrated light intensity. But, even though the integrated light intensity is the same, there are cases where your material would not cure due to low illuminance.

So, in conclusion, it is often possible to increase the amount of time spent under weak illuminance to achieve the same curing effect as strong illuminance, but there is a threshold at which the illuminance is simply too low to cure at all. This threshold depends on the material that’s being cured.

More Calculation Examples

Imagine you have a conveyor line - each sample passes under the light of a UV LED. This LED has a width of 5 mm and 1000 mW/cm².

When passing at a speed of 5 mm/sec, 1000 mW/cm 2 of light shines onthe sample for 1 second. So, our cumulative illuminance calculation:

1000 mW x 1 sec = 1000 mJ/cm 2

When passing at a speed of 20 mm/sec, 1000 mW/cm 2 of light shine on the sample for 0.25 seconds. So our cumulative illuminance calculation:

1000 mW x 0.25 seconds=250 mJ/cm 2

In other words, when passing under the UV LED irradiator with the same illuminance and the same width, the cumulative light amount (total light intensity) will differ depending on the conveyor’s speed. If your sample passes at a speed 4 times faster, the total illuminance will be 1/4. That’s why the strength of the UV LED system is so crucial. A higher power irradiator can counter the effects of faster conveyor.

Here we have a conveyor with a speed of 20mm/second, and a UV LED illuminator with a strength of 4000mW and an illumination area that’s 5mm wide. Each sample will spend 1/4 second in that area.

Cumulative illumination will be 1000 mJ/cm2.

Here we have a conveyor with a speed of 20mm/second, and a UV LED illuminator with a strength of 1000mW and an illumination area that’s 20mm wide. Each sample will spend 1 second in that area.

Cumulative illumination will be 1000 mJ/cm2.

A high powered illuminator can also reduce the size of your production line. Both of these illuminators impart 1000 mJ/cm 2. But figure uses a more powerful illuminator that produces a more narrow area of illumination.

So ultimately, strong illuminators can reduce production times and factory floor footprints substantially. Our UVWx400x20 is one of our strongest UV LED illuminators, with a form factor that gives it high total illuminance.

It’s important to remember, though, that all of this is a simplification of the UV energy transfer. Some materials behave a little differently, or require time to cure - for example, some materials will continue to cure for several hours after UV exposure. But this simplification is a good rule of thumb and starting point to calculating what sort of UV LED system your application needs.